Walk into an airport, and you’ll see chaos tamed into precision. Flights leave within minutes of their scheduled time. Ground crews know exactly when a plane will arrive, how long it will stay, and what’s needed before takeoff. It’s a finely tuned dance that keeps passengers moving and revenue flowing.

Now, look at most auto garages.

- Bookings overlap

- Jobs run late

- Customers wait

The contrast is clear: airlines operate with dynamic scheduling, while many garages still rely on sticky notes and guesswork. This contrast is proof that manual business methods do not even hold a candle to modern technology.

If you want your shop to run smoother, smarter, and more profitably, it’s time to start thinking like an airline.

Why Dynamic Scheduling Matters

Scheduling is not a sidekick for airlines; it’s their lifeblood. One delay cascades across multiple flights, impacting passengers, crews, and profits.

Garages face the same reality. A late delivery of parts, a no-show technician, or an underestimated repair time doesn’t just affect one customer. It pushes back the entire day’s workflow.

Dynamic scheduling gives you the flexibility to adjust in real time. That means jobs get reshuffled without panic. Customers stay informed instead of frustrated. And your team knows exactly what to tackle next without wasting time figuring it out.

Technology as the Control Tower

Here’s where tools make the leap possible. With auto garage management software, you can automate the parts of scheduling that drain your time and energy.

The system:

- Tracks technician availability

- Repair durations

- Monitors customer history to build schedules

It also integrates with parts inventory, so you don’t promise jobs you can’t deliver because a critical part is sitting in transit.

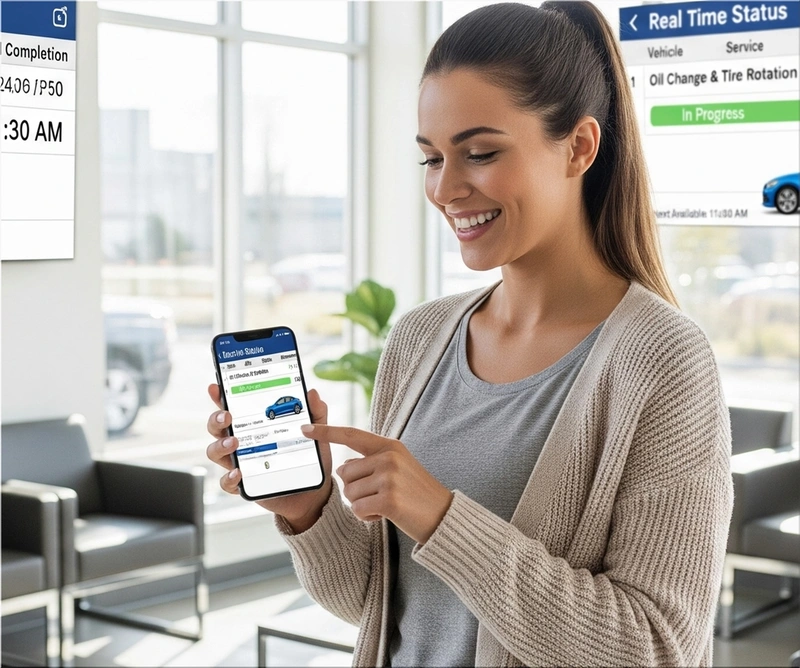

Customers benefit too. Instead of vague timelines, they get accurate updates, just like flight notifications. They know when their car will be ready, and if there’s a delay, they’re told before they have to ask. That transparency builds trust, which builds loyalty.

Turning Guesswork into Precision

Traditional scheduling in garages often looks like a block calendar. Drop-offs at 9 AM, pickups by 5 PM. Simple but dangerously misleading.

Not every job takes the same time. Not every customer arrives on time. Not every tech has the same skill set.

Smart operations go deeper. They match the right technician to the right job. They factor in prep time, cleanup, and the likelihood of follow-up work. It’s about accuracy, not hope.

Airlines don’t schedule a jumbo jet turnaround the same way they schedule a regional flight, and neither should your garage treat all jobs as equal.

The Cost of Standing Still

Some garage owners shrug at the idea of dynamic scheduling. Why? Because they have always done it this way.

But standing still is riskier than moving forward.

- Inefficient scheduling bleeds money quietly

- Technicians sit idle while waiting for parts

- Customers walk out when wait times spiral

- Managers waste hours every week just juggling paperwork

Airlines that relied on guesswork would be out of business in weeks. Garages don’t face that scale of pressure, but the principle is the same. Poor scheduling erodes efficiency, frustrates staff, and eventually sends customers to competitors who run tighter operations.

Borrowing from Airline Playbooks

So, what lessons can garages borrow directly from airlines? Curious much? Let’s find out.

Real-time Updates

Airlines notify passengers of delays instantly. Garages should do the same with customers.

Resource Optimization

Airlines match planes, crews, and gates with precision. Garages should match jobs, technicians, and bays.

Predictive Planning

Airlines analyze data to forecast demand. Garages can do the same by studying busy seasons, repeat customers, and high-demand services.

Turnaround Efficiency

Airlines minimize ground time. Garages can minimize downtime by preparing parts and tools before a car even rolls in.

These aren’t lofty concepts; they’re practical habits that modern technology makes possible.

Building Smarter, Not Busier

Busy doesn’t always mean profitable. Airlines aren’t profitable because planes are always in the air. They’re profitable because those flights are scheduled, staffed, and maintained with precision. Garages need the same mindset.

Dynamic scheduling reduces waste, but it also creates opportunities. When jobs are managed cleanly, technicians can take on more work without feeling stretched thin. Customers leave happier, return more often, and refer their friends.

Profit isn’t squeezed from chaos; it’s earned through control.

The Future is Already Here

How can you take care of electric vehicles, which are the new norm, with outdated assistance? The truth is, dynamic scheduling isn’t futuristic. It’s already happening.

The best garages are embracing digital tools, streamlining operations, and keeping customers informed every step of the way. Those who resist? They’ll be left behind, just as outdated airlines fade out when they fail to adapt.

Thinking like an airline isn’t about adding more complexity. It’s about simplifying with intelligence. It’s about letting systems do the heavy lifting so your team can focus on what they do best—fixing cars and serving customers.

Final Approach

Airlines know that every minute counts. Every gate assignment, every crew shift, every notification is designed to keep the system moving without disruption. Garages should take note.

Dynamic scheduling and smart operations aren’t buzzwords anymore. they’re competitive necessities. With the right mindset and the right tools, you can turn your garage into a well-oiled machine that runs with airline-level precision. The skies are clear for those ready to make the shift.