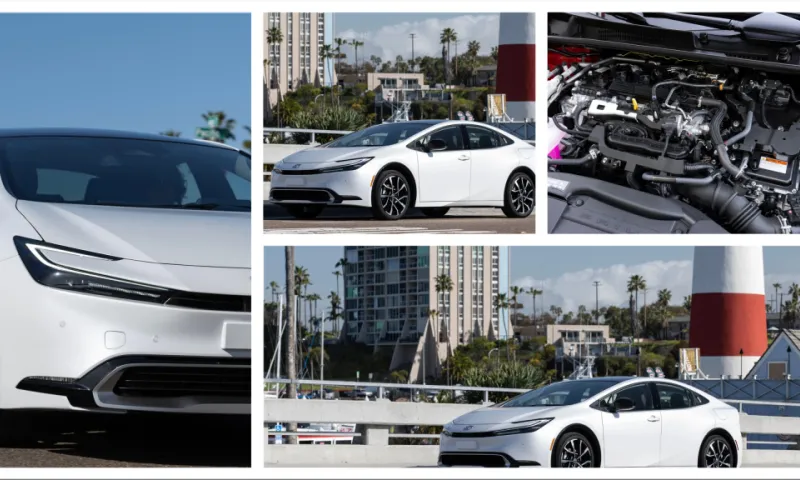

Toyota Motor North America announced an additional $88 million investment in its Buffalo, West Virginia plant. This move strengthens Toyota's push to increase hybrid electric vehicle (HEV) production in the United States.

This latest investment will boost capacity for hybrid transaxles. The transaxles are essential components in hybrid powertrains, playing a key role in fuel efficiency and performance.

Toyota's investment signals continued confidence in U.S. manufacturing and the future of hybrids as consumer demand shifts.

Table of Contents

- Investment Breakdown

- Why Toyota Focuses on Hybrid Expansion

- Impact on West Virginia Plant Operations

- Job Creation and Workforce Development

- Hybrid Transaxle Production: Why It Matters

- Toyota’s Broader Electrification Strategy

- U.S. Auto Market and Hybrid Demand

- Summary Table: Toyota West Virginia Plant Investments

- Conclusion

1. Investment Breakdown

Toyota will allocate the $88 million to:

- Expand capacity for hybrid transaxle production.

- Increase assembly capabilities for engine parts and hybrid systems.

- Upgrade machining and assembly equipment to improve efficiency.

This expansion follows Toyota’s prior $1.8 billion investment at the same plant since operations began.

2. Why Toyota Focuses on Hybrid Expansion

Toyota remains committed to hybrid technology. The company sees hybrids as a practical way to reduce emissions without relying on full battery electric vehicles (BEVs).

Reasons for this strategy:

- Hybrids reduce emissions while maintaining long driving ranges.

- Hybrids offer affordability compared to BEVs.

- Existing infrastructure supports hybrid vehicle usage.

Toyota aims to sell 1.5 to 1.8 million electrified vehicles annually in the U.S. by 2030, including hybrids, plug-in hybrids (PHEVs), and BEVs.

3. Impact on West Virginia Plant Operations

The Toyota Motor Manufacturing West Virginia (TMMWV) facility produces:

- Hybrid transaxles

- Four-cylinder engines

- Six-cylinder engines

The new investment will:

- Increase hybrid transaxle output.

- Support Toyota’s growing hybrid lineup.

- Enhance machining and assembly processes.

The plant already has 2,000 employees. This investment will provide further training and upskilling opportunities for the current workforce.

4. Job Creation and Workforce Development

While Toyota did not specify new job numbers tied directly to this investment, the company emphasized:

- Ongoing workforce development.

- Training to support advanced hybrid systems production.

- Skills upgrades for handling precision machining and assembly.

TMMWV remains one of the largest employers in the region.

5. Hybrid Transaxle Production: Why It Matters

The hybrid transaxle combines the function of a transmission and an electric motor generator. It is critical for:

- Energy efficiency in hybrids.

- Smooth power delivery between gas engines and electric motors.

- Improving fuel economy and performance.

Toyota’s production of transaxles in the U.S. reduces supply chain risks and supports domestic hybrid vehicle production.

6. Toyota’s Broader Electrification Strategy

Toyota plans to invest $70 billion globally in vehicle electrification through 2030. This includes:

| Electrification Type | Example Models | Status |

|---|---|---|

| Hybrid Electric Vehicles | Toyota RAV4 Hybrid, Toyota Camry Hybrid | Available Now |

| Plug-in Hybrid Vehicles | Toyota Prius Prime | Available Now |

| Battery Electric Vehicles | Toyota bZ4X | Launching/Expanding |

| Hydrogen Fuel Cell Vehicles | Toyota Mirai | Available in select markets |

Toyota expects hybrids to remain a significant share of their sales mix over the next decade.